List of Sock Factories in Vietnam

Greetings and welcome to my humble virtual Vietnam abode. My name is Chris, and it is with utmost sincerity that I extend my warmest regards from Ho Chi Minh City, Vietnam. Since the year 2008, I have immersed myself in the captivating world of sourcing, driven by a genuine passion for helping others. How may I be of genuine assistance to you today? Are you ready to embark on a remarkable journey into overseas manufacturing? 🇻🇳

Allow me to paint a sincere portrait of my expertise. I have honed my skills in garment manufacturing and explored a tapestry of industries, including hats, bags, shoes, wallets, plastic injection molding, metal parts, furniture, ceramics, and beyond. However, let us focus our attention on the comforting realm of the sock factory in Vietnam.

Allow me to paint a sincere portrait of my expertise. I have honed my skills in garment manufacturing and explored a tapestry of industries, including hats, bags, shoes, wallets, plastic injection molding, metal parts, furniture, ceramics, and beyond. However, let us focus our attention on the comforting realm of the sock factory in Vietnam.

Services I Offer

eBooks

Courses

Consultation

Factory Introductions

Factory Tours

Production A to Z

When is a good time to schedule a time to talk?

Imagine the simple joy of slipping into a pair of socks meticulously crafted with care. The sock factory in Vietnam embodies craftsmanship and dedication, weaving threads of comfort and warmth. Together, let us unravel the possibilities within this realm, as I offer my sincere guidance and support.

Now, let us navigate the path that lies before you. Would you prefer to establish a direct partnership with the sock factory in Vietnam, fostering a genuine connection and overseeing every detail? Or perhaps you seek the guidance of a trusted agent, someone who can navigate the intricacies on your behalf? Rest assured, I am here to provide comprehensive services, including introductions to reputable sock factories and the opportunity to witness their sincere craftsmanship through enlightening tours.

To embark on this remarkable journey, I kindly invite you to schedule an introductory call, where we can engage in a genuine conversation about your specific needs. Together, we will navigate the intricate terrain of Vietnamese manufacturing, guided by sincerity and a shared vision of success.

Let's find a sock factory in Vietnam for you. Should you require further assistance or have any inquiries, please do not hesitate to reach out. It is my sincere desire to assist you on this meaningful journey into Vietnamese manufacturing. 🍀

Now, let us navigate the path that lies before you. Would you prefer to establish a direct partnership with the sock factory in Vietnam, fostering a genuine connection and overseeing every detail? Or perhaps you seek the guidance of a trusted agent, someone who can navigate the intricacies on your behalf? Rest assured, I am here to provide comprehensive services, including introductions to reputable sock factories and the opportunity to witness their sincere craftsmanship through enlightening tours.

To embark on this remarkable journey, I kindly invite you to schedule an introductory call, where we can engage in a genuine conversation about your specific needs. Together, we will navigate the intricate terrain of Vietnamese manufacturing, guided by sincerity and a shared vision of success.

Let's find a sock factory in Vietnam for you. Should you require further assistance or have any inquiries, please do not hesitate to reach out. It is my sincere desire to assist you on this meaningful journey into Vietnamese manufacturing. 🍀

Schedule a Factory Tour Today!

Let's talk about growing your business by manufacturing in Vietnam. This page is about sock manufacturing in Vietnam. More and more sock factories are opening up in Vietnam.

I offer services like factory introductions, factory visits and quality control. Contact me to find out who the best sock manufacturers are in Vietnam. I find the right factories fast for you in Vietnam.

I offer services like factory introductions, factory visits and quality control. Contact me to find out who the best sock manufacturers are in Vietnam. I find the right factories fast for you in Vietnam.

Socks manufacturing is not a high-tech industry, but the whole socks manufacturing process does involve many steps, and the coordination between these steps makes the whole process time-consuming. 10 years ago there was very little sock manufacturing going on in Vietnam not to mention the price was higher than China. Now the Vietnamese are getting smarter and have opened up local sock factories. In the sock production end, socks manufacturing factories have to consider lots of things such as: Yarn choice, yarn color accuracy, knitting machine needles, Sock sizes, weight, production lead time, sock quality inspection, sock packaging and private labeling, Import tax and VAT, international delivery are services I can help you with.

1. Pattern coding

You provide sock companies in Vietnam the sock designs, they will need a professional coding team who are familiar with sock pattern and machine mechanism to transfer your vector designs into bitmap designs and then codes that the knitting machines can read. Why do they have to do this extra step? Because sock knitting machine are not that intelligent to read the designs directly. Every pixel of the bitmap design means a thread with the specific color will be knitted through.

You provide sock companies in Vietnam the sock designs, they will need a professional coding team who are familiar with sock pattern and machine mechanism to transfer your vector designs into bitmap designs and then codes that the knitting machines can read. Why do they have to do this extra step? Because sock knitting machine are not that intelligent to read the designs directly. Every pixel of the bitmap design means a thread with the specific color will be knitted through.

2. Yarn preparation

Make sure you confirm the 2 import things about yarns with sock companies in Vietnam: composition and colors.

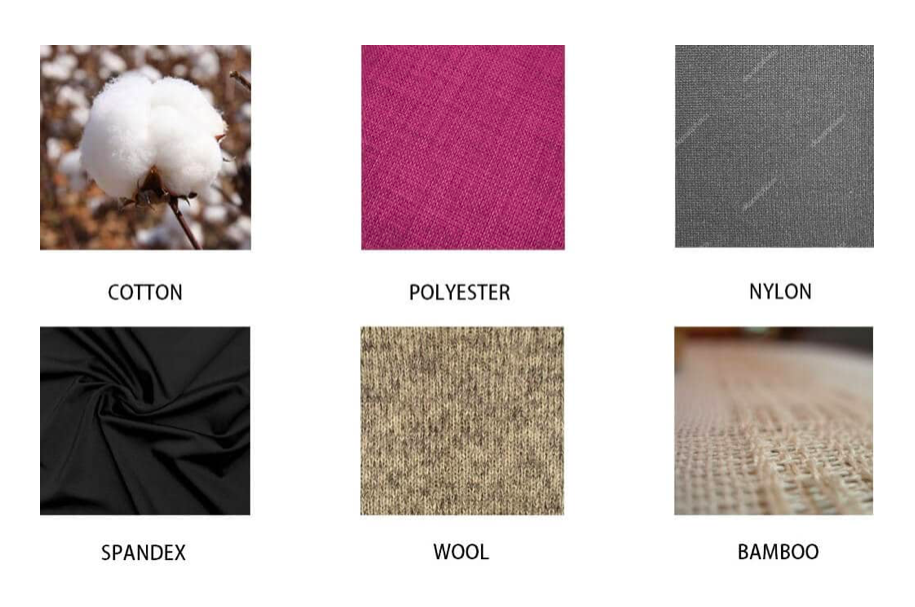

Generally, you only need to know 6 kinds of yarns, since 95% of the socks are manufactured using these materials.

Make sure you confirm the 2 import things about yarns with sock companies in Vietnam: composition and colors.

Generally, you only need to know 6 kinds of yarns, since 95% of the socks are manufactured using these materials.

Color accuracy is one of the most important things in custom socks manufacturing. To ensure the socks are of the same color as designed, we suggest our clients to use Pantone TCX colors reference. There are 3 ways that you can find pantone tcx colors for your design:

Buy a pantone cotton passport (FHIC200).

Use Pantone color manager (free if you purchase a pantone color passport).

Match pantone tcx colors using online free official tools.

3. Knitting socks

Using programmed codes in step 1, multitude of needles then knit the various threads into a series of interlocking loops. Computerized sock knitting machines work at high speeds and can easily be programmed to produce a wide variety of socks. 1st inline-inspection is implemented here to avoid mistakes like length, trimming, interlocking etc.

Buy a pantone cotton passport (FHIC200).

Use Pantone color manager (free if you purchase a pantone color passport).

Match pantone tcx colors using online free official tools.

3. Knitting socks

Using programmed codes in step 1, multitude of needles then knit the various threads into a series of interlocking loops. Computerized sock knitting machines work at high speeds and can easily be programmed to produce a wide variety of socks. 1st inline-inspection is implemented here to avoid mistakes like length, trimming, interlocking etc.

4. Linking/Sewing socks

Knitting makes a cylinder tube, thus we need to the sewing process in order to link the seperated toe parts together. This is usually done by machine, which is quick. Sometimes this process is also done by manual work, which costs a lot of time. Since the socks are sewed one by one, our skilled workers can easily find defective socks and clear them away from the majority, which is the 2nd inline-inspection.

6. Pairing & Labelling socks

This is the final inspection step to make sure there is no deflection on the socks. The left and right socks are paired together and then passed on to be private labelled. You can choose hangtags or bands to label your socks.

Knitting makes a cylinder tube, thus we need to the sewing process in order to link the seperated toe parts together. This is usually done by machine, which is quick. Sometimes this process is also done by manual work, which costs a lot of time. Since the socks are sewed one by one, our skilled workers can easily find defective socks and clear them away from the majority, which is the 2nd inline-inspection.

6. Pairing & Labelling socks

This is the final inspection step to make sure there is no deflection on the socks. The left and right socks are paired together and then passed on to be private labelled. You can choose hangtags or bands to label your socks.

5. Boarding

The boarding process is actually implemented to keep the socks in good shape, so that they can easily be paired and packed. One more thing to note here is that sock companies in Vietnam keep the socks clean and soft by experiencing steams under a fixed pressure and temperature in the boarding step. After boarding, the socks will naturally dried.

The boarding process is actually implemented to keep the socks in good shape, so that they can easily be paired and packed. One more thing to note here is that sock companies in Vietnam keep the socks clean and soft by experiencing steams under a fixed pressure and temperature in the boarding step. After boarding, the socks will naturally dried.

Many customers came to us and told us the truth that they could easily find sock companies in Vietnam on Alibaba or on Google search, but here are the things they had to encounter:

When they spent several days communicating with the suppliers but there was low chance for them to get a reply from the factory. Try it yourself and you will know the pain.

Most sales don’t know to “follow-up” with your order status.

50% don’t write in good English and 90% of them don’t speak in fluent English.

They only answer what you are asking but don't offer advice like shipping, labeling, etc.

We have good sock companies in Vietnam in our database as we visited their factories and we have been working with them for years. We make sure they are active in responding to your order, speak English well and have certifications that meet your demands.

We know the sock companies in Vietnam that can produce a variety of socks including daily cotton socks, sport socks, function socks and silk goods such as dress socks, casual socks, patterned socks, plane socks, toe socks, yoga socks, baby socks, men's socks, kid's socks, tights, shool socks, skiing socks, hiking socks, football socks, baseball socks, function socks, silk socks, silk scarf, silk gloves and etc..

Yes, you can do small quantity sock manufacturing in Vietnam. But there is low chance for you to do business with sock companies in Vietnam with small order just to test the viability of their concept. Because their price will be too high to cover for shipment fixed costs (LCL “Less than container load”), set-up charges and profit. We think small quantities don’t work when sourcing in Vietnam.

After we give you the contact info of the factory, you can work directly with them and ask them this question. Each factory will have different manufacturing lead time. Generally, Vietnam is still very dependent on importing raw materials…about 70% of them are imported from China. This issue will equate to longer lead-times and potentially a stoppage in production if just one component part is delayed.

We recommend you have tech packs prepared in advance to email factories. You don't know what tech pack is?

Our sourcing company in Vietnam is smaller than many other quality consulting services and therefore are easily compatible to a particular requirement of each customer. Big companies cannot control the knowledge of their inspectors. An inspector who does the inspection of shoes may do it the same way for apparels. So how good is that inspection? A good technical knowledge of the product is a must. Moreover, big agencies don’t know the customers either – so the inspector does not actually know the need of a specific customer. We can educate each inspector of exactly what each customer needs. Therefore, our reports are accurate and dedicated to the needs of the customer.

When they spent several days communicating with the suppliers but there was low chance for them to get a reply from the factory. Try it yourself and you will know the pain.

Most sales don’t know to “follow-up” with your order status.

50% don’t write in good English and 90% of them don’t speak in fluent English.

They only answer what you are asking but don't offer advice like shipping, labeling, etc.

We have good sock companies in Vietnam in our database as we visited their factories and we have been working with them for years. We make sure they are active in responding to your order, speak English well and have certifications that meet your demands.

We know the sock companies in Vietnam that can produce a variety of socks including daily cotton socks, sport socks, function socks and silk goods such as dress socks, casual socks, patterned socks, plane socks, toe socks, yoga socks, baby socks, men's socks, kid's socks, tights, shool socks, skiing socks, hiking socks, football socks, baseball socks, function socks, silk socks, silk scarf, silk gloves and etc..

Yes, you can do small quantity sock manufacturing in Vietnam. But there is low chance for you to do business with sock companies in Vietnam with small order just to test the viability of their concept. Because their price will be too high to cover for shipment fixed costs (LCL “Less than container load”), set-up charges and profit. We think small quantities don’t work when sourcing in Vietnam.

After we give you the contact info of the factory, you can work directly with them and ask them this question. Each factory will have different manufacturing lead time. Generally, Vietnam is still very dependent on importing raw materials…about 70% of them are imported from China. This issue will equate to longer lead-times and potentially a stoppage in production if just one component part is delayed.

We recommend you have tech packs prepared in advance to email factories. You don't know what tech pack is?

Our sourcing company in Vietnam is smaller than many other quality consulting services and therefore are easily compatible to a particular requirement of each customer. Big companies cannot control the knowledge of their inspectors. An inspector who does the inspection of shoes may do it the same way for apparels. So how good is that inspection? A good technical knowledge of the product is a must. Moreover, big agencies don’t know the customers either – so the inspector does not actually know the need of a specific customer. We can educate each inspector of exactly what each customer needs. Therefore, our reports are accurate and dedicated to the needs of the customer.